-1.png)

Basic Parameters

- Bag size: max. 285mm×570mm min.60mm×90mm.

- Maximum bag sorting speed: 300 cuts per minute.

- 3 basic channels, up to 4 channels at maximum.

Basic Functions

- Horizontal production mode (Vertical production is accessible after selecting the vertical mode).

- Automatic defects removal in bundles.

- Suitable for bag making machines of two-step cutting.

Operation process description

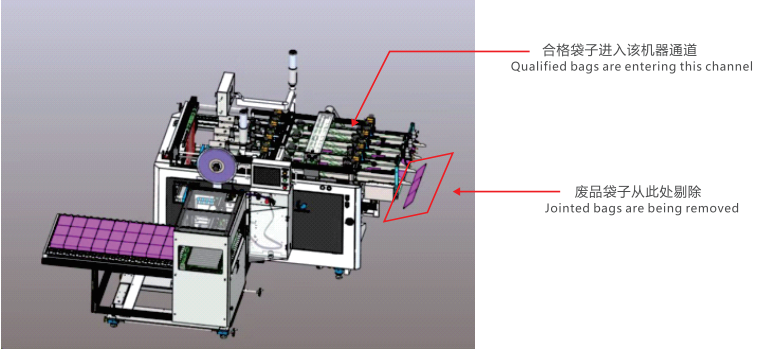

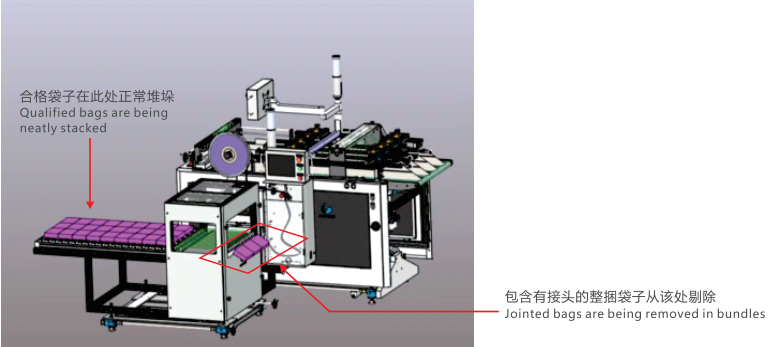

Unlike the basic version, the bags are not stacked directly at the cutting edge of the bag-making machine after production. Instead, they enter the bag sorting machine channel one by one. If there are defective bags, they are rejected downwards during transport at the channel opening. If there are no defective bags, they are transported forward one by one and then stacked on the receiving platform. After reaching a certain quantity, they are automatically tied together and then transported to the stacking platform for stacking.https://youtube.com/shorts/KVogvK7E6UY?si=9CI0OPg-IfYHJ_Er

-1024x709.png)

Use cases for automatic defect rejection

A.Online visual inspection + bag sorting machine rejection device

The online visual inspection system is installed on the bag making machine, and the rejection device is installed on the bag sorting machine; the two can be system-linked. The online visual inspection system can identify problems such as missing prints, misprints, scratches, and stains on the film. After identification, it transmits signals to the bag sorting machine, tracking their positions in real time. When these defective films are made into bags and conveyed to the bag sorting machine, the machine will perform a downward rejection action, ensuring that only good bags are conveyed forward, thereby improving the overall bag quality and meeting customers’ high-quality bag requirements.

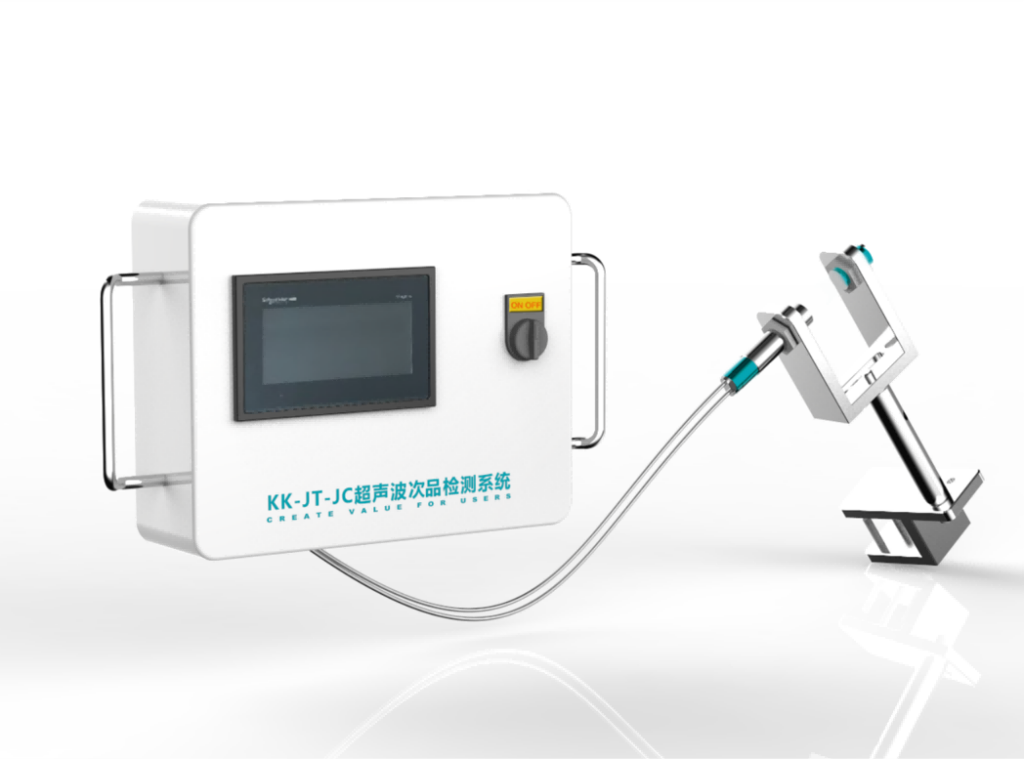

B.Ultrasonic joint detection + bag sorting machine rejection device

When changing films for different products, tape is applied to the joints between the films. This section of film is considered waste and must be rejected. The ultrasonic joint detection system, installed on the bag making machine, can identify changes in film thickness and locate film joints. When these joints enter the bag sorting machine, they are also identified and then rejected downwards, thus ensuring the overall bag quality and reducing film waste.

Detailed display of defects removal function

Defects removal in bundles

Typically used to remove the jointed bags and its adjacent bags.

Defect removal in single

Mainly used to remove single-piece jointed bag.